Evaluation of the Hydrophilicity of Silicone Hydrogels Using Sudan IV

Purpose: The aim of the study was to visualise hydrophobic areas of silicone hydrogels on the surface and in the bulk (core material) using a saturated solution of Sudan IV. In addition, the influence of the all-in-one solution Opti-Free Puremoist (MPS) and an artificial tear solution (ATS) on the hydrophobic areas was investigated.

Material and Methods: Within the scope of the study, two target values of the silicone hydrogels Balafilcon A, Balafilcon A (2), Samfilcon A, Comfilcon A and Fanfilcon A were compared with the hydrogel material Ocufilcon D in vitro. The absorption coefficient was determined using a spectrometer (Spectro 100, Fa. Instrument Systems), while the total percentage staining was analysed graphically using the ImageJ software. The variation in the staining time enabled a differentiated staining of the hydrophobic areas on the surface (30 min) and in the core material (16 h).

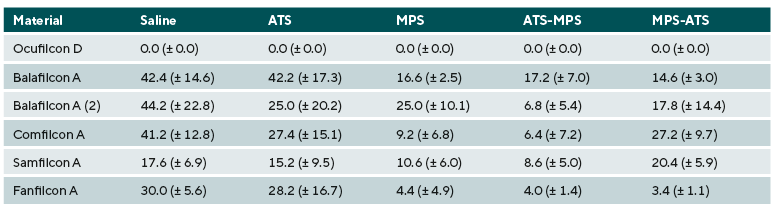

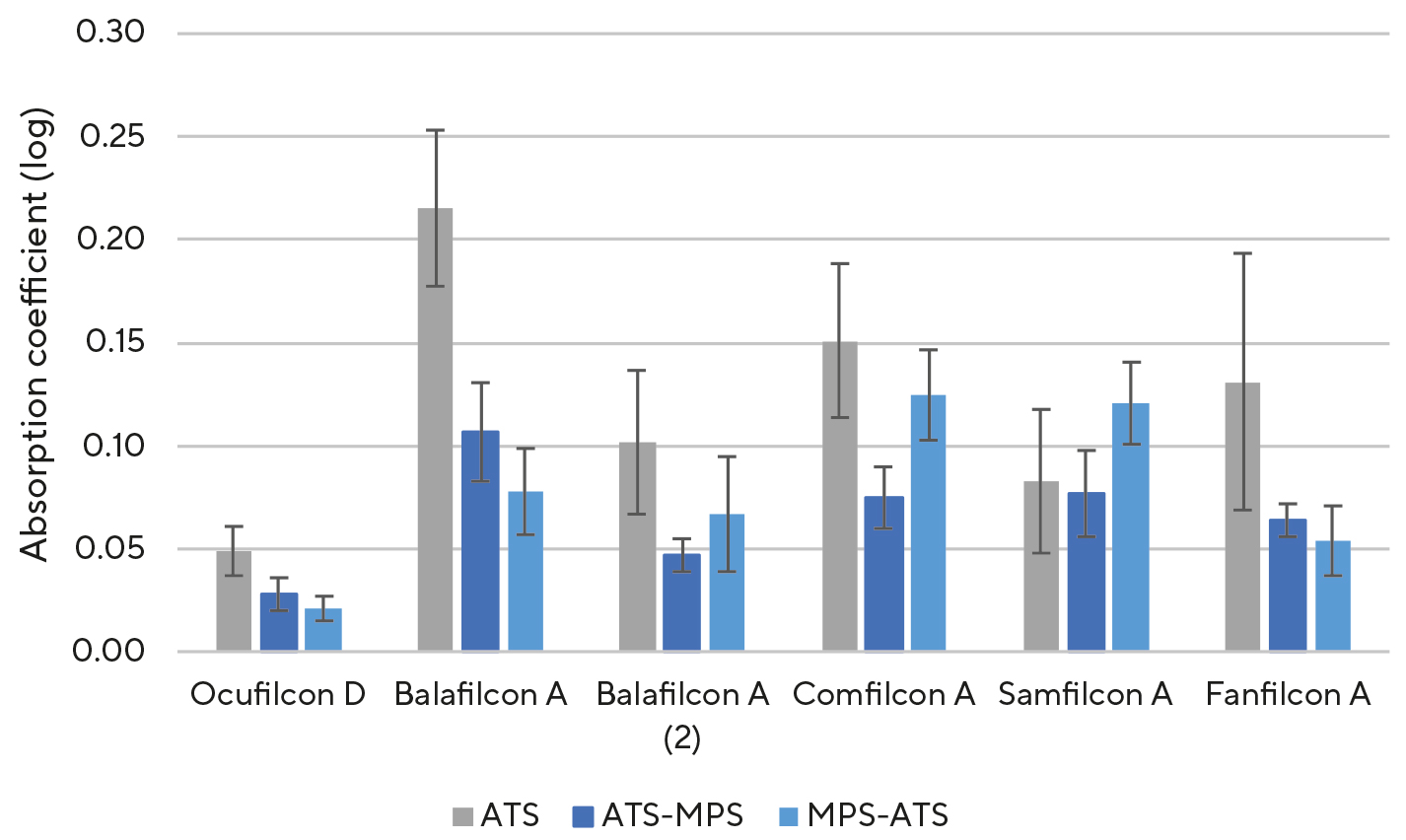

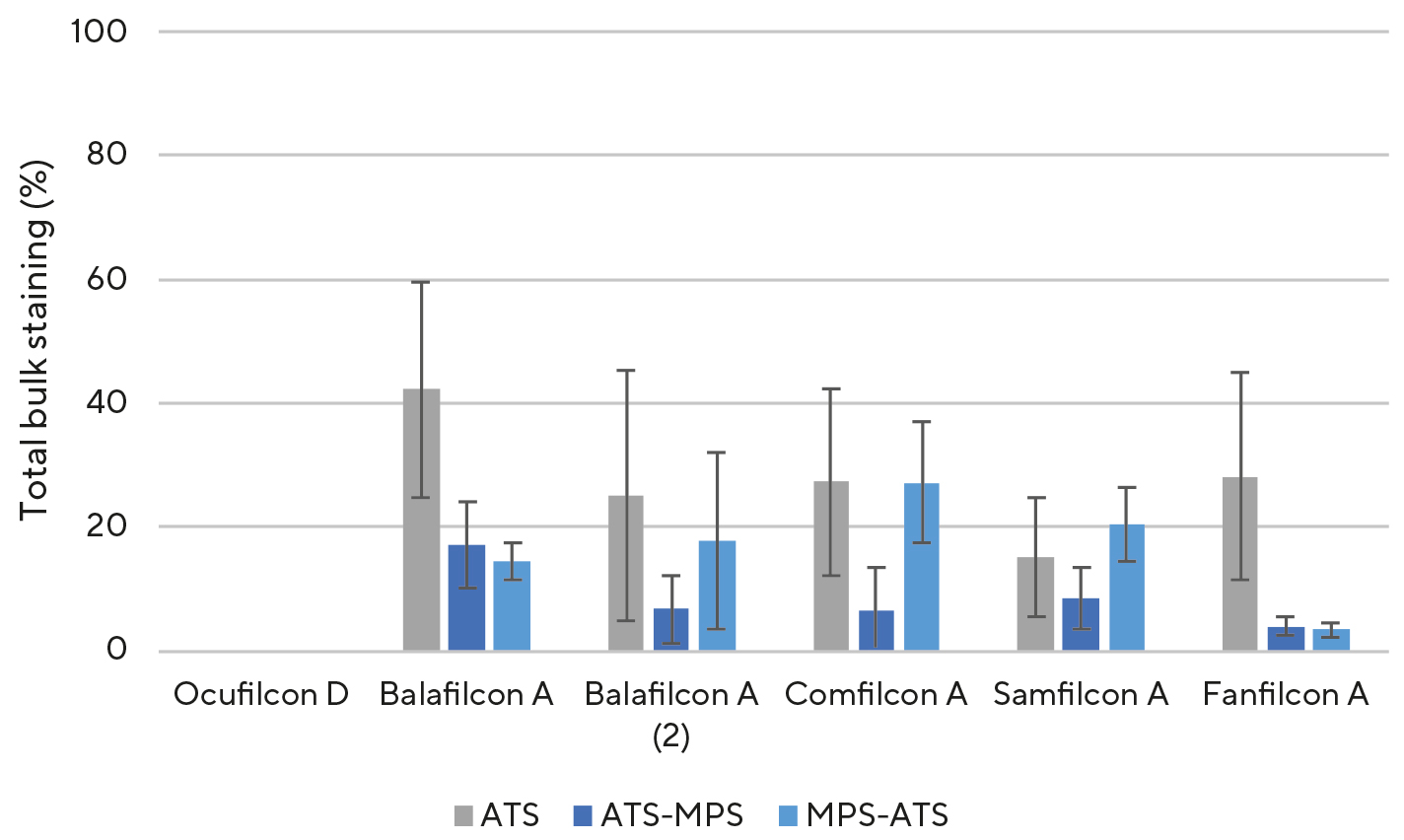

Results: Superficially, the silicone hydrogels exhibited comparable hydrophilic properties to the hydrogel. In the core material, however, statistically significantly more hydrophobic areas could be stained. MPS was able to effectively reduce the hydrophobic areas of monthly disposable contact lenses previously inserted in ATS. The following values for total staining and absorption coefficient were obtained for exposure with ATS: Ocufilcon D (0.0 % // 0.049), Balafilcon A (42.2 % // 0.0215), Balafilcon A (2) (25.0 % // 0.102), Comfilcon A (27.4 % // 0.151), Samfilcon A (15.2 % // 0.083) and Fanfilcon A (28.2 % // 0.131). After the examination sequence with ATS-MPS, the following measurement data were determined: Ocufilcon D (0.0 % // 0.028) Balafilcon A (17.2 % // 0.107), Balafilcon A (2) (6.8 % // 0.047), Comfilcon A (6.4 % // 0.075) Samfilcon A (8.6 % // 0.077) and Fanfilcon A (4.0 % // 0.064). The reduction was statistically significant for all materials, with the exception of Samfilcon A (p < 0.001).

Conclusion: The use of Sudan IV made it possible to Colour specific hydrophobic areas. Specific differences for different materials had been identified.

Introduction

5.0 % of the German population aged 16 and over wear con-tact lenses (as of 2024).1 Soft weekly and monthly contact lenses are the most commonly worn types.1 The classic hydrogels have long been replaced by silicone hydrogels, which have taken the market lead.2,3,4 The main reason for this lies in the silicone content of the material, which gives it its name. This ensures a high oxygen permeability, supplying the entire cornea sufficiently with oxygen 5 and reducing or eliminating hypoxic problems associated with the use of hydrogels.6 However, silicone not only has high gas permeability but is also hydrophobic.7 The hydrophobic areas caused by the silicone content in the material can form bonds. Silicone hydrogels therefor offer a higher potential for lipid biofouling 8,9 and lipid deposits.10,11 Furthermore, insufficient wettability leads to increased surface roughness,12 which reduces wearing comfort.13 Therefore, contact lens manufacturers have de-veloped new technologies since the introduction of the first silicone hydrogel contact lens to improve the wettability of the lenses.14,15,16 To evaluate the wettability of a contact lens in vitro, two main methods are primarily used in research: the sessile drop method and the captive bubble method.17,18,19,20,21 Both methods are based on contact angle measurements and allow an assessment of the surface wettability of a contact lens. However, only a rough categorization is possible from the evaluation of these methods. It is not possible to make statements about the localization or extent of hydrophobic areas on the contact lens. It is also not possible to assess the hydrophobic areas that are located in the core material (bulk) of the contact lens. A method for visualising hydro-phobic areas using the dye Sudan IV enables a more detailed description of hydrophobic areas, both on the surface and within the bulk.22 Hydrophobic areas in the bulk material are of particular interest because components of the tear film, depending on the material properties, can penetrate into the interior of the lens and be absorbed there. Such hydrophobic areas could preferentially interact with lipids and thus contribute to the formation of biological deposits on or within the lens.23,24 Within the scope of this study, this method was used to investigate various silicone hydrogels with regard to their hydrophobic properties.

Objective of the study

The objective of this study was to compare hydrophobic areas located on the surface and within the bulk of hydrogels and silicone hydrogels. In addition, an artificial tear fluid was used to induce deposition effects, and the effectiveness of an all-in-one contact lens care solution in minimizing hydrophobic areas was investigated. The investigation and analysis of hydrophobic regions were carried out separately for both the entire contact lens and the optical zone.

Materials and Methods

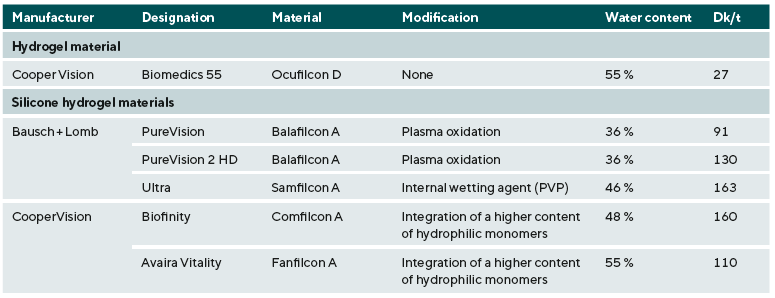

The study was conducted as an unblinded, prospective, single-centre investigation. All data were collected in vitro. A total of 300 monthly contact lenses with a dioptric power of −3.00 D were examined. One hydrogel and four silicone hydrogel materials were investigated, including a design-enhanced version of Balafilcon A, referred to hereafter as Balafilcon A (2), which is characterized by higher oxygen permeability. For linguistic simplicity, this enhanced material is treated as a separate material. The contact lens materials used are listed in Table 1.

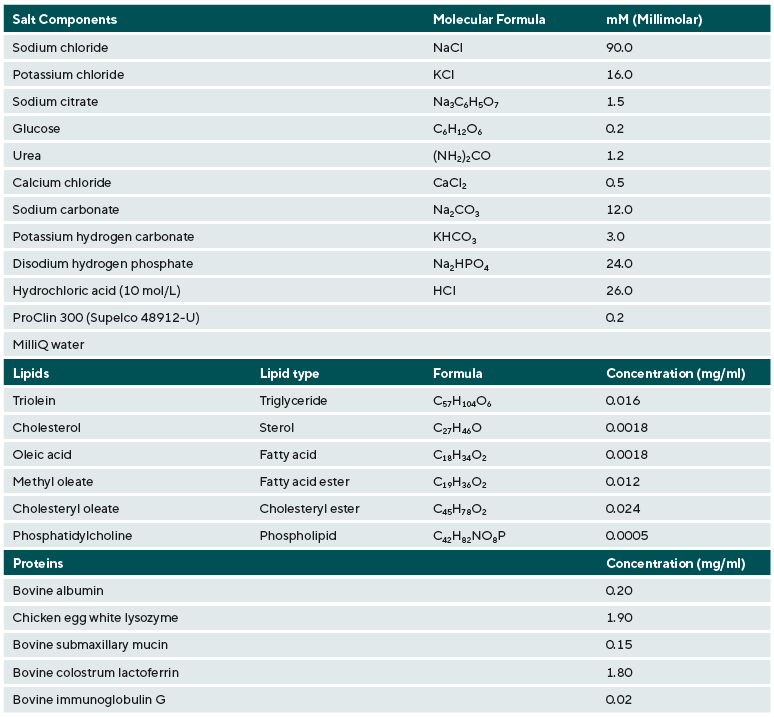

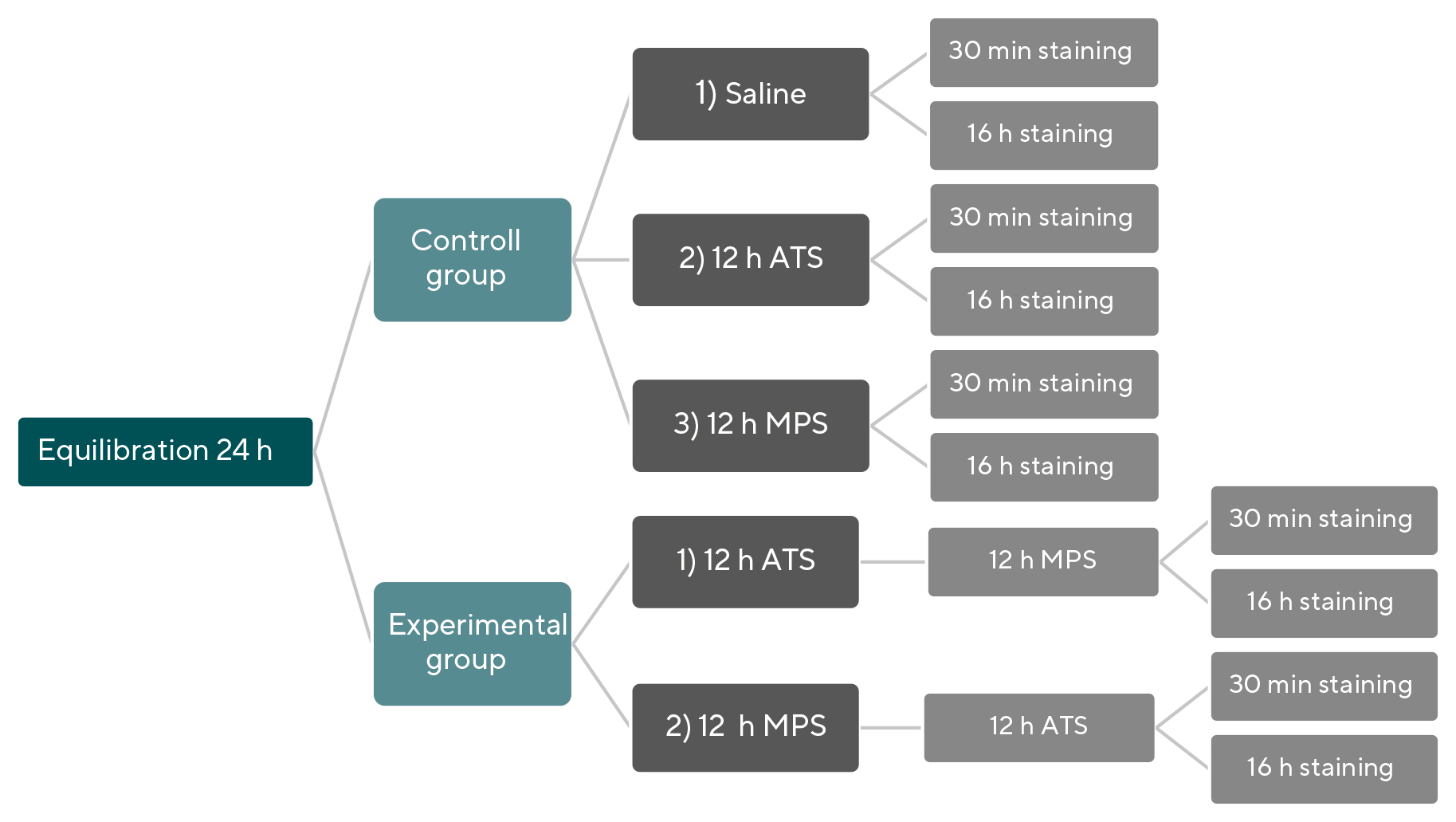

The Sudan IV dye (Sigma-Aldrich Laboratory and Produc-tion Materials, CAS: 63148-62-9) was prepared using a highly pure silicone oil (Sigma-Aldrich Laboratory and Production Materials, CAS: 63148-62-9) with low viscosity (~10 cSt) to prepare a 2 % solution. During the measurements, hydro-phobic areas present on the surface and within the bulk were visualised using the Sudan IV solution. Prior to this, the contact lenses were equilibrated for 24 hours in standard-ized saline solution (Saline, Appenzeller), with a pH value of 6.447,25 and subsequently exposed for 12 hours either to an artificial tear solution (ATS) 26 or an all-in-one solution (MPS), in order to investigate their influence on the staining of the hydrophobic regions. The artificial tear solution had a pH value ranging from 7.35 to 7.49 and an osmolality between 303.7 and 305.0 mmol/kg.26 Three exposures served as controls, while two additional experimental sequences (two consecu-tive exposures were used for the experiment). In the control groups, the isolated effects of saline, the artificial tear solution (ATS), and the all-in-one solution Opti-Free Puremoist (MPS) were examined. In the first experimental group, following the 12-hour equilibration in saline, the contact lenses were placed into ATS for 12 hours and subsequently into MPS for 12 hours. This test sequence corresponded to wearing contact lenses all day, placing them in an all-in-one solution for cleaning in the evening, and removing them from the contact lens case the next morning. This experimental group allowed an assessment of the effectiveness of the all-in-one solution in reducing hydrophobic areas, without additional mechanical rubbing. In the second experimental group, the order of MPS and ATS was reversed. This experimental sequence corresponded to the all-day wear of contact lenses, which were cleaned overnight and inserted in the morning. This experimental group allowed an assessment of the hydrophilisation of the contact lenses through MPS. The composition of the tear solution is provided in Table 2.26

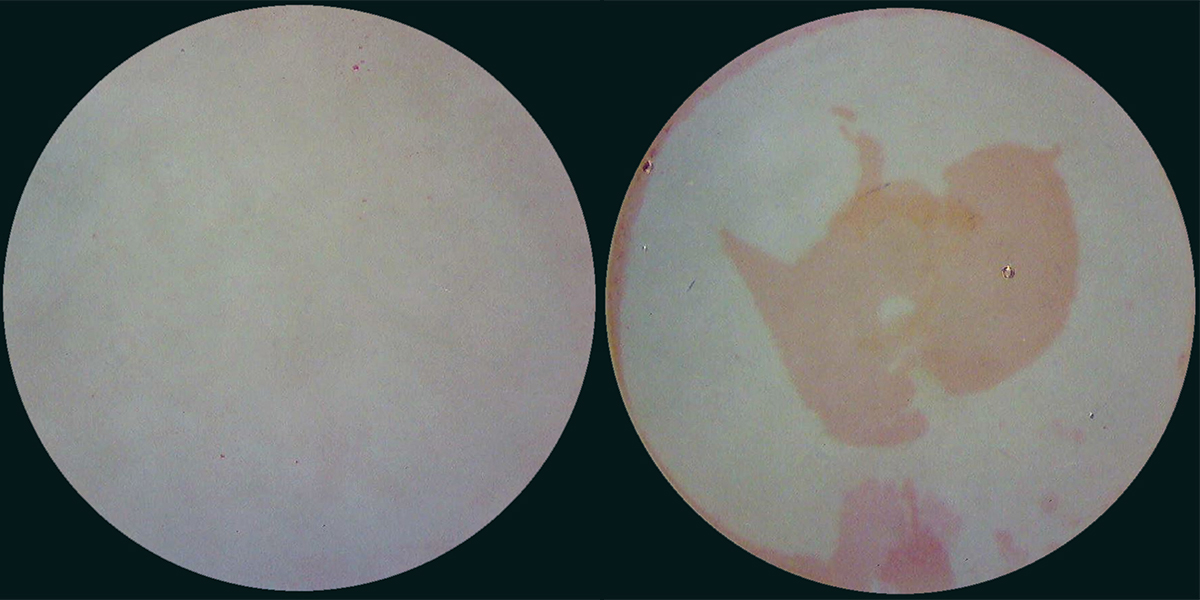

The sample comprised 10 contact lenses per exposure or experimental sequence, with 5 lenses stained superficially and 5 stained within the core material (bulk). For the super-ficial staining (Figure 2), the contact lenses were soaked in a dye mixture consisting of 2 % Sudan IV and silicone oil for 30 minutes. For the bulk staining (Figure 3), the soaking time was 16 hours. The staining durations were determined based on the study by Jacob et al. and their preceding preliminary studies.22

The contact lenses were transferred directly after exposure into dye-filled well plates. Using tweezers, the lenses were positioned with the apex facing upward, ensuring that they were fully immersed in the staining solution up to the apex and did not adhere to the edges of the wells during the soaking period. Throughout the entire staining period, no visually detectable inhomogeneities were observed in the solution that would indicate a phase separation between Sudan IV and the silicone oil. Staining was carried out at room temperature (22 °C) without the use of a shaking platform. After staining, the contact lenses were rinsed with saline solution, and excess dye was gently dabbed off using a lintfree cloth. The staining was analysed using a light microscope (Stemi 305, Zeiss) and documented with a built-in-camera.

Within the study, two target parameters were determined. On one hand, the influence of staining within the optical zone on the target parameter, the absorption coefficient at 522 nm, was investigated. Whereby the wavelength of 522 nm corresponds to the absorption maximum of the dye. Furthermore, the total staining was determined as a percentage in relation to the overall size of the contact lens. The measurement data were collected unpaired.

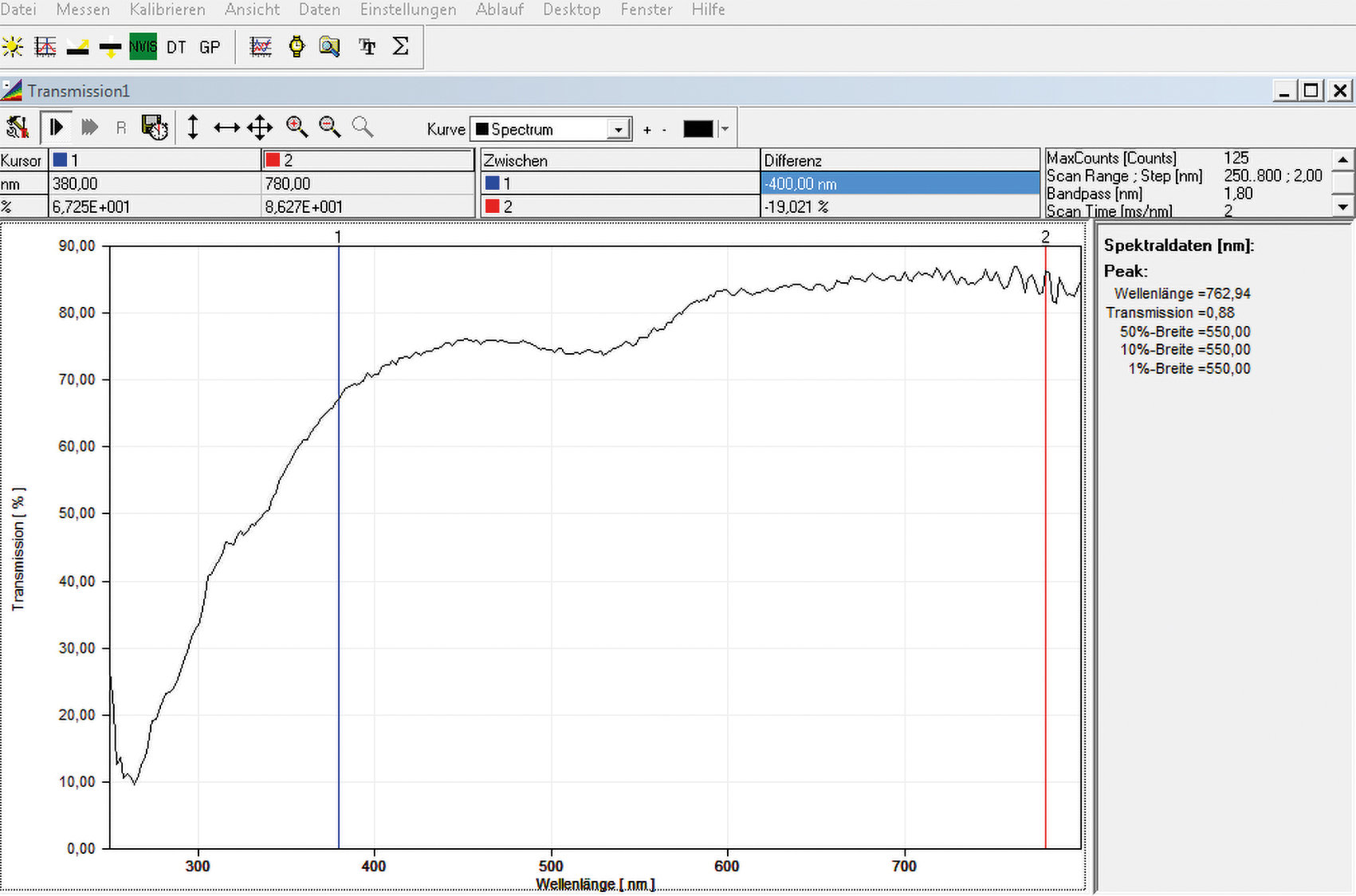

Measurement of the Absorption Coefficient

To determine the absorption coefficient or extinction, a spec-trometer (Spectro 100, Fa. Instrument Systems) was used. The measurement of the transmittance was performed at a wavelength of 522 nm in the central, optically relevant area of the contact lens with a diameter of 6 mm (Figure 4). The listed values are based on the averaging of 25 individual measurements. Subsequently, the absorption coefficient was calculated as follows:

τ (λ) = (ΔΦet (λ)) / (ΔΦei (λ))

= (Φet (λ) • Δ (λ)) / (Φei (λ) • Δ (λ)) (1)

τ (λ) = spectral transmittance

Φet (λ) = transmittance spectral radiant power

Φei (λ) = incident spectral radiant power

ε (λ) = log10 (1 / τ (λ)) (2)

τ (λ) = spectral transmittance

ε (λ) = absorption coefficient

The measurement conditions complied with the applicable DIN ISO 18369-3:2018-04 standards.

Determination of the Percentage of Total Staining

To determine the percentage of total staining, image Analysis was performed using the software Image J. Microscopic images were used for this purpose. The program evaluates the images on a pixel basis, meaning that pixels had to be specifically selected in advance, which were then elated to the total number of pixels. The staining of the contact lenses appeared inhomogeneous and varied in intensity. Therefore, to graphically determine the total staining of a lens, a threshold value was defined. This threshold was based on the red values of a reference image of saline solution, which is considered transparent and thus unstained.

The evaluation of the red staining takes place in the RGB colour space: high staining intensity is detected in the red value range of 0–24 (strong red), low intensity is detected in the range of 195–255 (pink) and classified accordingly.

Statistical Analysis

The collected data were statistically analysed using SPSS 29. Due to the small sample size of n = 5 per group, no definitiveconclusions could be drawn regarding normal distribution and homogeneity. Therefore, normal distribution and homogeneity of the data were assumed for the analysis. For hypothesis testing, the parametric ANOVA test for more than two unpaired samples was used. The results of the analysisof variance (ANOVA) are considered significant at p < 0.05.

Results

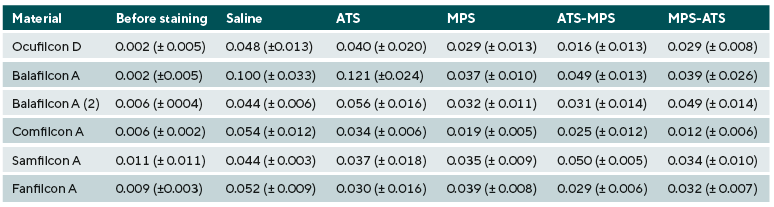

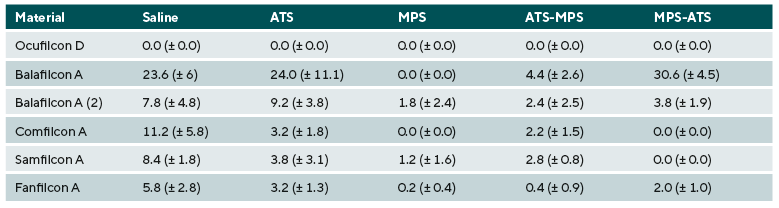

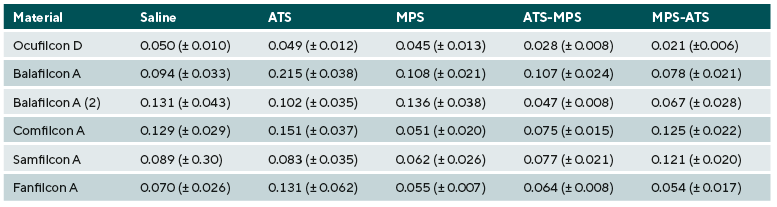

The determined mean values with the corresponding standard deviations are presented in the following tables, sorted by the measured target parameter and the type of staining.

Superficial Staining

- Absorption Coefficient (Table 3)

- Percentage Staining (Table 4)

Staining in the Core Material

- Absorption Coefficient (Table 5)

- Percentage Staining (Table 6)

All silicone hydrogel contact lens materials showed a superficial hydrophilicity with respect to the two assessed target parameters, comparable to that of the hydrogel Ocufilcon D, with the exception of Balafilcon A. In the bulk, all unworn silicone hydrogels showed significantly higher total staining compared to Ocufilcon D (p < 0.001; for Samfilcon A p = 0.003). In addition, for the materials Balafilcon A (p = 0.019), Balafilcon A (2), and Comfilcon A (p < 0.001), a higher absorption coefficient was determined for the unworn contact lenses compared to the hydrogel. ATS-MPS reduced both the total staining and the absorption coefficient of all silicone hydrogels (p < 0.001), with the exception of Samfilcon A, compared to ATS (see Figures 5 and 6). MPS-ATS reduced only the total staining and absorption coefficient of Balafilcon A and Fanfilcon A (p < 0.001) compared to ATS (Figures 5 and 6). No visible staining could be detected or graphically determined for the hydrogel Ocufilcon D.

Discussion

Based on the study by Jacob et al., it was to be expected that silicone hydrogels would exhibit more hydrophobic regions both on the surface and within the core material (bulk) compared to conventional hydrogels.22 Consequently, these materials would show greater staining with Sudan IV. This applies to staining of both the entire contact lens and the optical zone. However, with regard to superficial staining, no differences were observed between the silicone hydrogels and the hydrogel Ocufilcon D across any of the tested exposures or experimental sequences. An exception to this was the material Balafilcon A. Therefore, the surface of modern contact lenses appears to exhibit good wettability, comparable to that of hydrogels. Moreover, the hydrophobic regions of the Balafilcon A material were effectively reduced after contact with the all-in-one solution used. The quantitative analysis of surface staining by Jacob et al. also demonstrated a pronounced staining of the material Balafilcon A.22 This staining was markedly more intense compared to other materials. This trend is consistent with the results observed and graphically analysed in the present study.

In contrast to the superficial staining, all silicone hydrogel materials showed statistically significantly higher bulk staining compared to the hydrogel material Ocufilcon D. Additionally, all silicone hydrogel materials except for Samfilcon A and Fanfilcon A showed a reduced transmission due to staining of the optical zone. Therefore, the stated hypothesis for bulk-stained contact lenses was confirmed. Jacob et al. also observed a statistically significantly higher bulk staining for all tested silicone hydrogel materials.22

The following section provides a more detailed analysis of the effects of the experimental groups on the parameters measured after bulk staining. The visualisation of hydrophobic spots after exposure of the lenses to an all-in-one solution, following soaking in artificial tear solution (ATS), aims to assess the efficacy of the MPS in removing deposited ATS-components.22 Therefore, staining is compared between control group 2 (ATS) and experimental group 1 (ATS-MPS). The graphical analysis of total staining and the measurement of absorption in the optical zone revealed a statistically significant reduction of hydrophobic spots for all materials except Samfilcon A. In this comparison, all materials except Balafilcon A showed a total staining similar to that of the hydrogels. Regarding the optical zone, the reduction of hydrophobic spots was effective only for Balafilcon A (2) and Fanfilcon A, to an extent that hydrophilicity comparable to the hydrogel material was achieved. The all-in-one solution can effectively remove hydrophobic ATS components or form a protective layer on the contact lens, thereby increasing hydrophilicity and improving wettability. However, this applies only when considering the entire contact lens. Within the optical zone, hydrophobic spots could not be effectively reduced. Jacob et al. also observed a significant reduction in bulk staining across all tested contact lenses in their study.22

The visualisation of hydrophobic spots in contact lenses that were soaked in ATS following exposure to the all-in-one solution (MPS-ATS sequence) aimed to evaluate the hydrophilising effect of the MPS. Based on the comparative study by Jacob et al., it was assumed that lenses stained with Sudan IV after the MPS-ATS sequence would exhibit staining levels similar to those observed after ATS exposure alone.22 Such a result would indicate that MPS was not effective in hydrophilisation and that components of the tear solution form stronger bonds with the lens material than the molecules of the all-in-one solution.

In this study, the experimental sequence MPS-ATS led to total staining and optical zone staining that was similar to or higher than that observed with the independent variable ATS in all silicone hydrogel materials, except for Balafilcon A and Fanfilcon A. Notably, ATS exposure in Balafilcon A and Fan-filcon A resulted in significantly higher staining in the optical zone compared to the experimental sequence MPS-ATS. Regarding total staining, the MPS-ATS sequence was significantly more effective than ATS alone for both Balafilcon A and Fanfilcon A. The all-in-one solution resulted in effective hydrophilisation of the Fanfilcon A material. Subsequently, the material exhibited hydrophilic properties comparable to those of the tested hydrogel. In line with the findings of Jacob et al., the all-in-one solution was, for the most part, not effective in hydrophilising the silicone hydrogel materials. An exception to this was the material Fanfilcon A.22

Jacob et al. observed that contact lenses stained more intensely in the periphery than in the centre. From this, they concluded that staining is independent of lens thickness.22 This trend could not be confirmed in the present study: here, the contact lenses exhibited more intense staining in the central region, along with correspondingly higher absorption coefficients. This suggests that staining may, in fact, correlate with the thickness of the contact lens.

The measurement results cannot be generalized. This study only simulated the single use and the single cleaning of contact lenses. However, monthly lenses are worn for 30 days. With longer wear duration, lipid deposits increase, which may form hydrophobic areas.27 On the other hand, Cheng et al. demonstrated that mucins from the tear film can improve wettability over prolonged wear.28 A longterm follow-up study could provide insights not only into whether contact lenses become more wettable over the course of wear, but also into where hydrophobic areas may regress. Furthermore, this was an in vitro study in which the real-world wearing conditions described by Jacob et al. could not be simulated.22

A laboratory based simulation of the blinking process including associated friction, dehydration and tear exchange was also not conducted. Additionally, an artificial and idealized tear solution was used. Symptomatic contact lens wearers often exhibit a disrupted tear film, which can further impair lens wettability.29 This factor could not be accounted for within the scope of this study. A subsequent study could be designed to address this issue. Another limitation to consider is that only one cleaning agent, the all-in-one solution OFPM, was used in this study. Zhao et al. confirmed that different care solutions have material-dependent effects on the removal of cholesterol and proteins.30 With regard to the microscopic assessment of staining, it must be noted that due to the use of light microscopy, precise depth localization of the staining was not possible. For an accurate analysis of the staining depth, the use of confocal microscopy would be required.

The staining did not follow a consistent pattern and showed high variability within the same material. The staining patterns of contact lenses of the same type varied despite identical exposure/ experimental sequences. Therefore, when interpreting the measurement results, it must be taken into account that mean values were used. The absorption coefficient was determined exclusively in the optical zone within a 6 mm diameter. Consequently, a high percentage of total staining may occur even with a low absorption coefficient if the central area remains unstained, and vice versa. The observed variation in staining patterns may be due to minor deviations in the manufacturing process, lipid absorption from the tear solution, material inhomogeneities, or influences related to the experimental method. These assumptions could not be further investigated within the scope of this study; therefore, no definitive explanation can be provided.

The distinction between superficial and bulk staining was based on the study by Jacob et al.22 However, it should be noted that superficial absorption was not measured separately from bulk absorption and therefore could not be evaluated in isolation.

Conclusion

Silicone hydrogels show comparable hydrophilic properties on the surface to classic hydrogels. However in bulk, silicone hydrogels show significantly more hydrophobic areas. These can potentially absorb lipids from the tear film. The use of all-in-one solutions may help reduce hydrophobicity in the core material and thus counteract undesirable lipid deposition.

Conflict of interest

The authors declare that there is no conflict of interests re-garding the methods and devices mentioned in the article.

sphaerische-linsen/acuvue-oasys-1-day, Referencing: 16 November 2024.